Through this article, we will explore the changing mobility landscape and what type of magnet wires will best support e-mobility evolution.

Understand the EV Motors

Here are the things that make electric traction motors different from normal motors.

-

Inverter Fed

A regular motor is often plugged into a running electric source and hence operates directly on an Alternating Current (AC). Whereas, EV traction Motors gets its power from a battery. This demands an inverter to convert the Direct Current (DC) from battery to Alternating Current (AC) for the motor to function smoothly.

-

Frequent Acceleration and Deceleration

A moving vehicle needs to accelerate and decelerate frequently based on the road conditions. For an electric vehicle, this is achieved by changing the voltage and frequency of AC power delivered to the motor. The EV motor has to withstand these frequent power fluctuations.

-

Enhanced Starting Torque

EV motors need to deliver enhanced starting torque. This translates to quick acceleration and the ability to maintain power even when the vehicle is fully loaded.

-

Regenerative Braking

To conserve energy on the go during deceleration or braking, the kinetic energy from the spinning wheels is converted into electricity and fed to recharge the battery in EVs. The motor design should be able to cope with the challenges associated with regenerative braking.

To meet these specific needs of electric vehicles, their traction motors need to have magnet wires with special properties.

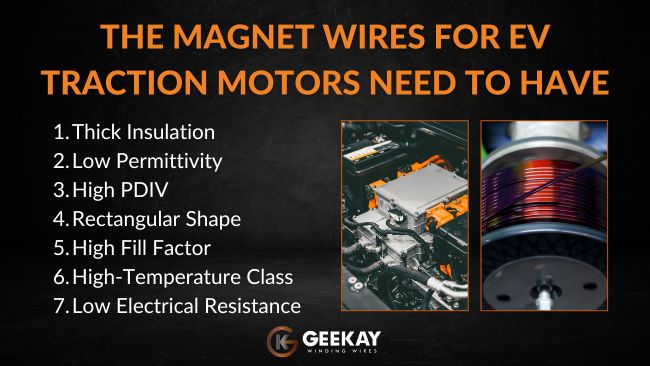

Special Magnet Wires for EV Traction Motors

High Power Density

For quicker acceleration and improved handling, the traction motor needs to deliver high power. This demands magnet wires with thicker insulations.

Excellent Electrical Efficiency

To achieve high performance and conserve energy, the motor should have minimum losses. In other words, the magnet wires should have the least resistance so that current losses are minimal. Copper winding wires possess high current carrying capacity in this regard.

High PDIV

Inverter-fed motors are subject to partial discharges due to spikes in the voltage supply. This can deteriorate the insulating enamel over a while, causing motor failure. Magnet wires for EVs thus need to have high PDIV (Partial Discharge Inception Voltage) to withstand these voltage fluctuations.

Great Mechanical Strength

Constant rotations and vibrations can make the operating environment of EV motors harsh. The magnet wires need to be robust to withstand the physical stress imposed on them to resist short circuits and wear and tear.

High-Temperature Resistance

To power the vehicle, the EV motor has to run continuously for long hours. This can cause heat build-up, and hence the magnet wires for EV motors need to have a high-temperature class.

Good Corrosion Resistance

EV motors are continuously exposed to moisture and chemicals. It can cause them to corrode in the long run. Using corrosion-resistant enamel insulations in winding wires can help maintain the structural integrity and performance of the motor in the long run.

Meet the space constraints

The vehicle design demands the motors to be compact and lightweight for easy manoeuvring. Rectangular magnet wires have a higher fill factor and help in this regard. [Read More: The Right Magnet Wire for EV – Round or Rectangular?]

EV technology is fast evolving, requiring magnet wire manufacturers to innovate newer designs and materials to keep abreast with the changing trends in EV motors, to improve their performance. EV motors require intricate winding patterns to optimize performance. Manufacturing wires to suit such complex needs with precision and accuracy consistently can be quite challenging. Hence choosing an experienced winding wire manufacturer is very important. [Read More: Tips to choose a winding wire supplier for EV]

GEEKAY is a specialist in magnet wire manufacturing to meet your EV needs

GEEKAY is highly specialized and experienced in manufacturing magnet wires that are at par with the latest in EV technology and are continuously adapting to evolving changes. We have the industry’s best technical know-how and expertise in manufacturing winding wires for optimal EV performance. GEEKAY’s dedicated technical support team is always available to answer your queries and give you a helping hand.

Contact us to initiate a chat on your special magnet wire requirements.