Magnet Wire or Enamelled wires, also known as Winding Wires are Copper (Cu) or Aluminium (Al) wires coated with a very thin layer of insulation. They are widely used in the manufacturing of transformers, inductors, motors, generators, electromagnets and other applications that require tight coils of insulated wire.

Types of Enamelled Wires

Like other wires, magnet or enamelled wire can be classified by the type of enamel used, diameter (AWG number, SWG or millimeters) or area (square millimeters), temperature class, and insulation class.

There are various types of enamels which are used in magnet wires to give them specific properties and make them appropriate for various kind of applications and benefits:

- PU: PolyUrethane

- PE: PolyEster

- PEI: PolyEster Imide

- PAI: PolyAmide Imide

- PI: PolyAmide

- PVF: PolyVinyl Formal

- SL : Self Lubricating

- SB: Self Bonding

Self-Lubricating Enamelled Wires

In this article, we will discuss Self Lubricating Enamelled Wires and their Features, Advantages & Applications.

Recently, to meet consumer demands, the electric appliance industry has moved towards product miniaturization and cost reduction. From a technical aspect, enamelled wire must be wound and packed very tightly, resulting in the winding speed becoming higher. Under this situation, the enamelled wire is subjected to severe mechanical stress and the enamel film is susceptible to damage and loss of insulating effectiveness.

One countermeasure to this problem is the use of self-lubricating enamelled wire with strong lubrication and abrasion resistance properties.

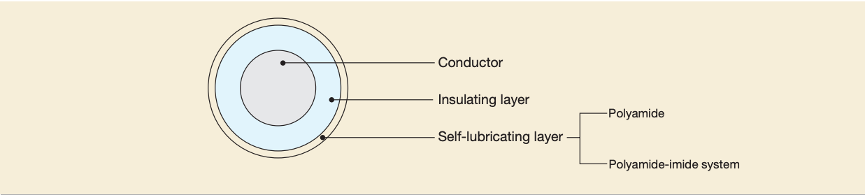

Self-lubricating enamelled wire structuring with some special self-lubrication material overcoat upon the outer layer of its film, it makes the wire a lower friction coefficient and better scrape-resistance; not only solving the high-speed winding problem, but also obtaining a better quality of the coils.

As the above figure shows, self-lubricating enamelled wire comes in two types, the usage of which is determined depending on the application.

Key Features of Self Lubricating Enamelled or Magnet Wires

- Excellent surface slip characteristics

- Good Mechanical Strength

- Suited for high-speed machine winding

- Good thermal shock resistance

Applications of Self Lubricating Enamelled or Magnet Wires

Self Lubricating Enamelled Wires can be used in all kinds of motors with high space factor such as motors for electrical equipment, auto electrical applications, Microwave oven, transformers & Magnet coils for heat-resistance components.

At Geekay, we produce the highest quality of Self Lubricating Enamelled Wires with temperature class from 1300C to 2000C in both copper and aluminium.