Copper winding wire is the first choice for most electrical and electronic applications involving electromagnetism. Be it motors, transformers or solenoids. The reason for this is the various benefits enamelled copper wire offers that make it suited for such high-performance demanding environments.

Let us see the benefits of copper magnet wire in detail.

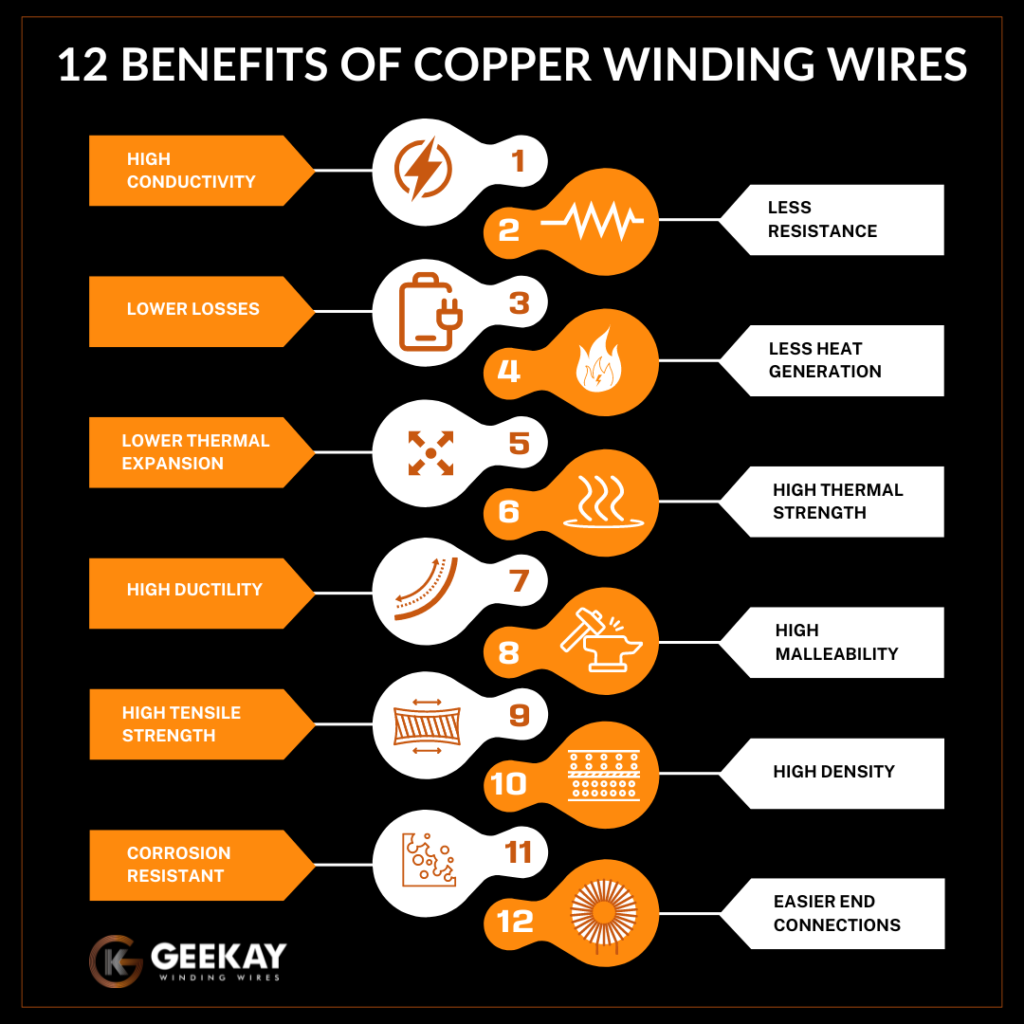

Benefits of Copper Winding Wires

1. High Conductivity

Copper as a metal has high conductivity, (58 MS/m at 20 °C). It can thus carry large amounts of current required to generate a strong magnetic field. In other words, copper winding wires can offer high BDV.

2. Less Resistance

The resistivity of copper is 1.724 x10-8 Ω⋅m This is quite low compared to other metals. Lower resistance makes copper a powerful current-carrying conductor.

3. Lower Losses

Since the resistivity is low, most of the current is transferred as it is. This translates to minimum electrical losses making enamelled copper wires highly energy efficient and suited for higher star-rated applications.

4. Low Heat Generation

Since copper offers the least resistance to the electric current flow, it produces less heat too. In the case of winding wire application where prolonged operation is expected, copper magnet wire is thus the most suited option.

5. Low Thermal Expansion

Copper undergoes lower thermal expansion, keeping the structural integrity intact even after continuous operation.

6. High Thermal Strength

Copper Winding Wires can be made using varying enamel insulations that can withstand higher temperatures. This makes enameled copper wires the best choice for highly efficient applications in harsh environments like that in electric vehicle traction motors.

7. High Ductility

Copper is highly ductile. This allows you to have winding wires of varying thickness without affecting the mechanical properties. Enameled Copper wires are thus the preferred choice for thin wire applications like noise-cancelling earphones and thicker wires in high-performing pumps.

8. High Malleability

The high malleability of copper enables it to be shaped as per the need. Round and Rectangular copper winding wires can thus be made using copper.

9. High Tensile Strength

Copper magnet wire has high tensile strength and is capable of withstanding mechanical stress. This also translates as high elongation for the winding wire. During the copper winding wire manufacturing, copper undergoes annealing to give softness to the winding wire. These mechanical properties of copper offer winding wire with very good softness. Soft copper wires make the winding process quite easy.

10. High Density

In comparison to other metals like Aluminium (2.7 g/cm3), copper (8.96 g/cm3) has a high density. This means that the current carrying capacity of copper magnet wire is more than that of aluminium magnet wire of the same dimension. This reduces the quantity of copper winding wire required for your application. And subsequently, makes them ideal for compact applications. In other words, copper winding wire offers a high fill factor.

11. High Corrosion Resistance

Copper corrodes at a slower rate, making it suitable for harsh or moist environmental conditions like in submersible pumps.

12. End Connections

Since copper doesn’t get oxidised fast, making end connections is an easy job. Even soldering or stripping the enamel layer can give you a fail-proof connection.

Due to its high mechanical properties, copper winding wire comes in varying sizes and shapes suiting your production needs. Copper offers good adhesion to different enamels, making it suited for various insulation classes. (Read More: Different Types of Copper Winding Wires)

Having said these, two things that are critical to reap the benefits of copper winding wires are the purity of copper used as well as the manufacturing process followed. (Read More: Impact of purity of copper in copper winding wires)

GEEKAY as a copper winding wire manufacturer

GEEKAY uses electrolytically refined copper with more than 99.99% purity. We follow a single line single oven to have uniform winding wire insulation properties. At GEEKAY, we make the copper winding wires undergo rigorous quality testing to ensure the thermal, mechanical, electrical and chemical properties of every batch is uniform and as per your specifications.

Having a strong R&D team and experience for more than 4 decades, we can make copper winding wires that are specially customised to your application. To get a sample, contact us with your technical specifications today.