A common query from our customers is ‘how to easily remove the enamel from magnet wires?’. Chemical removal takes anywhere between 5-45 minutes depending on the enamel type. On the other hand, mechanical removal is not the right approach and crimping is unsuitable for all types of wires.

Many organizations strive to constantly improve production efficiency by simplifying the enamel removal process. One definite way to achieve this is by switching to self-solderable winding wires.

Self-solderable winding wires (or self-soldering winding wires) are innovative magnet wires coated with solderable enamel. These special copper wires eliminate the tedious process of enamel removal, hence speeding up your assembly process.

Before understanding self-soldering wires, let us first understand why Enamel Removal could be a significant bottleneck in your manufacturing process.

Soldering the enamelled winding wire endpoints

In a normal assembly process, soldering the winding wire endpoints requires two steps: enamel removal and soldering. Enamel removal can be done chemically or mechanically, but both methods have drawbacks.

Chemical Enamel Removal – The winding wire endpoints are dipped in solvent chemicals for quite some time to remove enamel (say 5 to 45 minutes based on the enamel type). This process is time-consuming and is not feasible for the mass production of your products. Further, handling and disposing of chemicals need extra care as part of sustainable manufacturing practices.

Mechanical Enamel Removal– Here the enamel layer at endpoints is stripped off with physical means. This could possibly damage the winding wire and may also end up reducing the bare diameter at the area where the enamel is removed.

It is even critical in the case of thinner wires, as mechanical enamel removal can result in the breakage of the winding wire. And this may result in the entire coil being scrapped.

Mechanical enamel removal is most often used although it is not the ideal approach. Another method that is gaining traction is crimping, but it cannot be used for thinner wires.

Because of the extra care and time required, enamel removal can be the bottleneck in your manufacturing process. By switching to Self-soldering wire instead of traditional winding wire, you can get rid of the enamel removal step altogether. Here is how –

Using Self-Soldering Magnet Wires

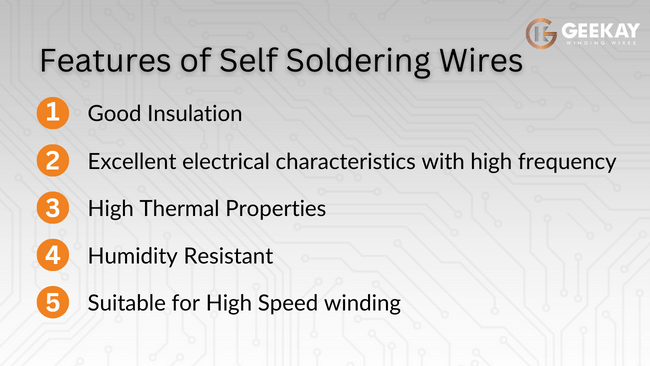

Self-soldering wires are winding wires with a special solderable enamel coating made of polyurethane (PU). These wires could be soldered directly without stripping off the enamel.

To solder the end connection with self-solderable wire, the winding wire is tied to the terminal. The terminal is then immersed in solder for 2 seconds. The PU enamel dissolves in the solder and the tied copper endpoint is soldered to the terminal simultaneously.

Apart from solderable Polyurethane, solderable PolyEsterImide can also be used as enamel for self-soldering wires based on your insulation requirements.

Advantages of Self-Solderable Wire

By using self-solderable copper wires, you can benefit as –

1. Increased Production Efficiency – Self-solderable wires club enamel removal and soldering into a single step, instead of a multi-stage process. This streamlines the assembly process and reduces the time and effort required.

On a whole, using self-solderable wires improves production efficiency and reduces manufacturing time. Of course, this in turn results in lower costs of operation and hence better margins for you.

2. Reliable Connections – Since the insulation layer dissolves in the solder bath, revealing bare copper for soldering, the inline diameter of the conductor is not altered.

Another benefit is that, since only the exact length of enamel in contact with the solder bath is removed, the conductor at the endpoint is perfectly soldered to the terminal. This also nullifies any possibility of exposed bare copper getting oxidised.

3. Easier maintenance of your line: Lesser steps in your manufacturing process means lesser machinery or lesser parts. Thus, eliminating the hassle of maintenance or manpower for enamel removal.

4. Complex joints – When there are multiple endpoints or complex joints, using self-solderable wire can make the connections easy and convenient. This is especially useful in the case of electronics industry where thinner magnet wires and complex joints are very common.

These advantages of self-soldering wires over traditional winding wires make them a good choice for most of the manufacturing process.

Things to note while using self-solderable magnet wires

Self-solderable magnet wire can be used in a wide range of applications including electric motors, generators, transformers, home appliances, switch gears, defence equipment, automotive, and electronics to name a few. Care should be taken to –

- Ensure the insulation does not have impurities – The presence of contaminants in the insulation layer can impact the soldering process, thus affecting the reliability of your products.

- Follow best winding practices – For accurate soldering and strong connections, proper spooling and process control should be there.

- Optional Enhancements – The solderable polyurethane copper winding wires (also known as UEW wires) can be overcoated with nylon to improve windability and abrasion resistance. They can also be overcoated with a self-bonding coat to make the winding more reliable and eliminate the process of impregnation.

Choosing a reliable self-solderable winding wire manufacturer is the key to ensuring quality and timely support.

Geekay Winding – A Trusted name in Self Solderable winding wire manufacturing

GK Winding is one of the leading organised winding wire manufacturers in India since 1975. We are driven by providing the finest quality winding wires of different technical specifications for various applications.

Innovation being one of our focus areas, custom-making wires based on your specific requirements is a key competency at Geekay Winding.

Get in touch with us with your requirement and specifications for a sample.