Copper wires are an integral part of electrical applications. Often, your procurement team may choose an enamelled copper wire vendor based on the lowest invoice price. But do you know that they may be using recycled or impure copper to reduce the prices?

In fact, recycled copper is 4% cheaper than virgin copper, hence it can drastically reduce the winding wire price.

First, let us understand What is impure copper?

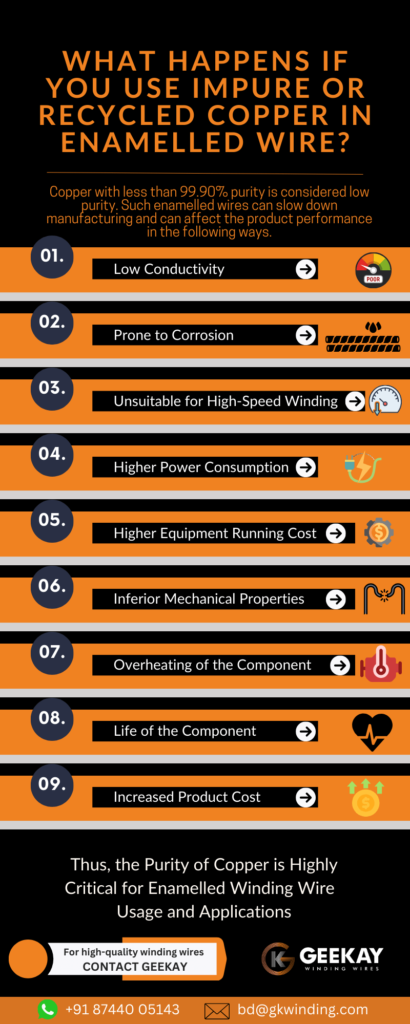

A copper with less than 99.90 % purity is said to be impure.

When using winding wires with such low purity, not only may you encounter many problems during the production process, but it affects the performance of your appliance as well.

Let us see what are the problems associated with using impure copper in enamelled winding wires.

Effects of Purity of Copper in Copper Wires

Using copper wires with a purity lower than 99.90% can result in –

1. Low Conductivity

Copper is widely used in electrical applications for its good conductivity. Yet the presence of impurities even in small amounts can affect the electrical conductivity of copper. For example, 0.05% of arsenic presence can bring down the conductivity by 15%.

Copper with lower purity may have impurities (like arsenic, phosphorous and aluminium) that can alter its desired electrical properties like BDV.

2. Prone to Corrosion

The presence of other particles facilitates faster corrosion in copper wires. This could result in pinholes and the formation of voids in enamelled wires. The presence of oxides also affects the electrical conductivity of copper wires.

3. Unsuitable for High-Speed Winding

Often, electrical motor winding follows a high-speed winding process for maximum efficiency and lesser production time. The winding wires made from recycled or impure copper are not suited for such high-speed winding.

It may break off while stretching and bending. This is caused by impurities such as lead, antimony, and bismuth, which disturb the copper crystallization process, making the wires very brittle.

4. Higher Power Consumption

Increased resistivity due to foreign particles translates to higher power consumption and increased current losses. So, making energy-efficient appliances is next to impossible if using impure enamelled copper winding wires. Modern-day energy-conscious consumers may find your products not so appealing because of this.

5. Higher equipment running cost

Higher power consumption can translate to higher equipment running costs. This could lead to customer dissatisfaction in the long run.

6. Inferior Mechanical properties

Not just electrical properties, but copper wires made of impure or recycled copper may not have good mechanical properties either. These may introduce damage to wires, abrasion, and bruises. They offer a lesser fill factor in the slots, making your appliance bulky.

7. Overheating

Higher resistivity due to impurities heats up the component while running. This can hamper the insulation properties leading to breakdown or short-circuits as well.

8. Life of the Component

Using winding wire with impure copper reduces the life of the component as it fails to operate at the prescribed levels. This may reduce its overall working life, increasing your warranty claims.

9. Increased cost of the product

Recycled copper maybe 4% cheaper than virgin copper. But when it comes to the quantity of copper required to achieve the same conductivity, it could be more in recycled copper than when using virgin copper. This may translate as an increased cost of up to 4-5% on the product due to higher copper consumption.

Moreover, this will increase the equipment’s weight, making the equipment bulkier and heavier.

As you can see here, using winding wire with recycled copper may look cheap in the beginning. But the added costs that come with that can turn it to be expensive in the long run.

Moreover, a product demands copper winding wire for its high-performance features. And, using winding wire with lower purity will defeat the purpose of reaping the benefits of copper winding wire.

Opting for copper winding wires made of virgin copper is the best option to ensure that your products meet the desired specifications and market demands.

Checking the purity of copper in every batch of wires could be a cause of production delay. Instead, choose a winding wire supplier who openly shares that they use virgin copper. Do look for quality certifications in them that affirm the same.

Geekay as a virgin copper winding wire supplier

Geekay is an established winding wire manufacturer focused on delivering high-quality copper winding wires for your needs. We use virgin copper with more than 99.99% purity to make copper magnet wires. We follow strict quality controls to ensure that Geekay winding wires meet technical specifications as per your demand.

Contact Us today with your requirements to see the quality advantage.